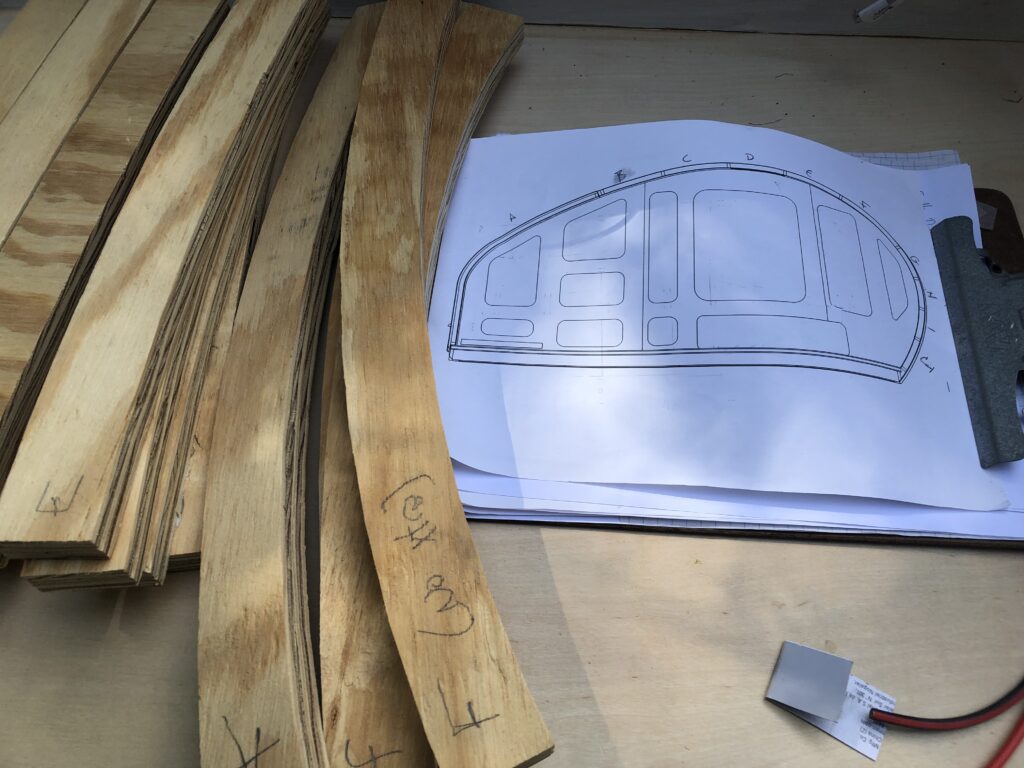

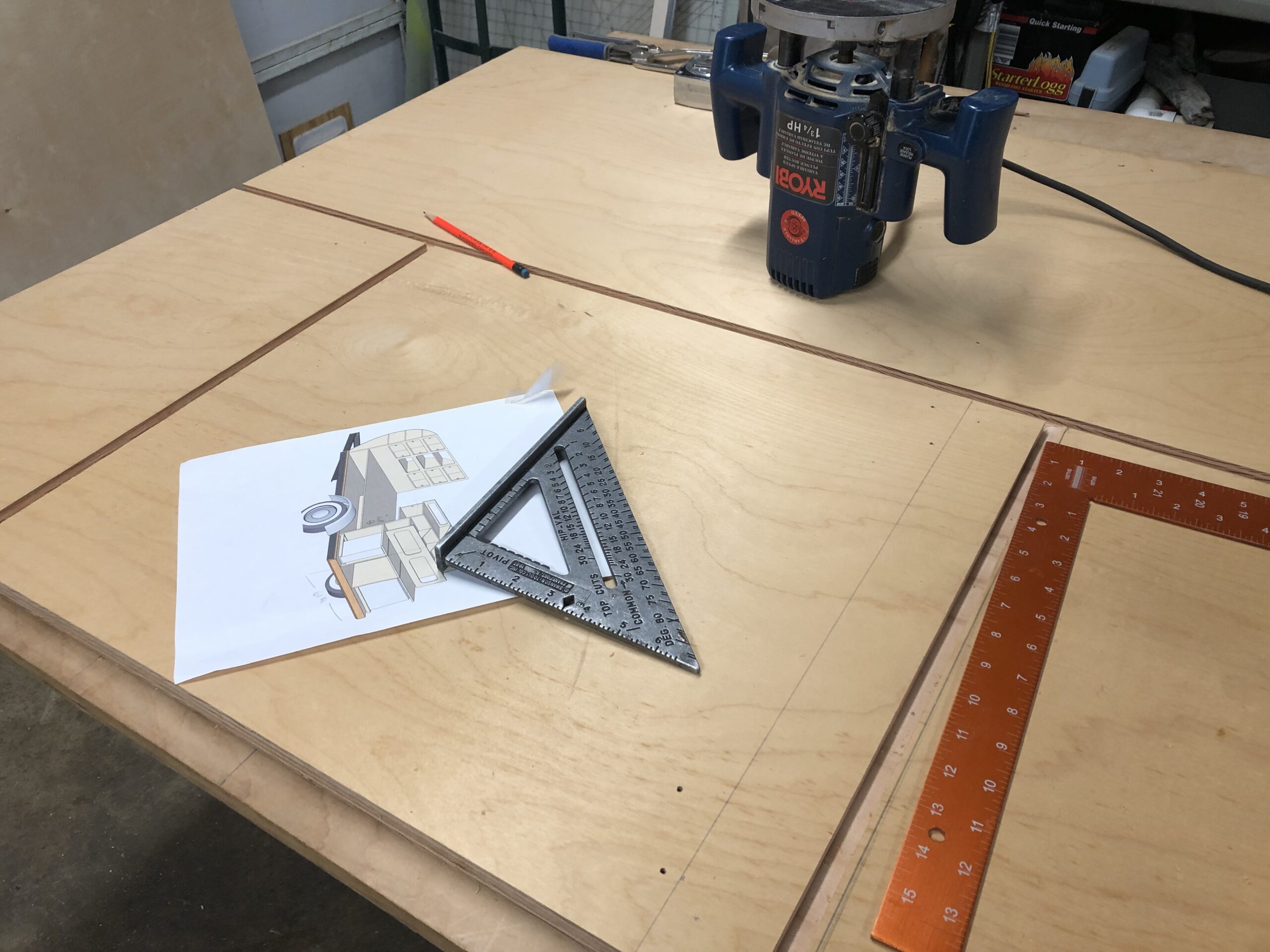

This has been a week of keeping multiple plates spinning as we near the end of the build. Electrical, roof liner, and cabinetry are all coming together.

Category: Blog

Rush Week

There was a hopeful plan where we wrapped up the major elements of the build in 11 days. Just a few days into this full-on build we realized it to be too ambitious. More than the physical challenges, it was the mental wear and tear that brought me down. Each step at this stage generally requires learning a new building technique, then applying it to some critical component of the build where there is no going back. It just about broke my brain.

So, we are taking a methodological approach, and hope to get the Betty Mobile road-ready by the first week in October.

We love you, Sitka!

Good gracious, I can’t believe it’s already been TEN DAYS since we left Sitka! I feel like I’m in one of those cartoons where the days are just flying off the calendar.

It was FANTASTIC to be back in Sitka. So nice to feel that fresh, cool Alaska air, see the beautiful mountains and islands, catch up with our friends, and check in on our little houses. We played some music, took nice walks, ate delicious meals, had so much great conversation, gave and received oh-so-many hugs, and soaked up as much as we could from our sweet town. Matthew got out to our friend’s cabin for a little kayaking one day, and I got to do a radio show!

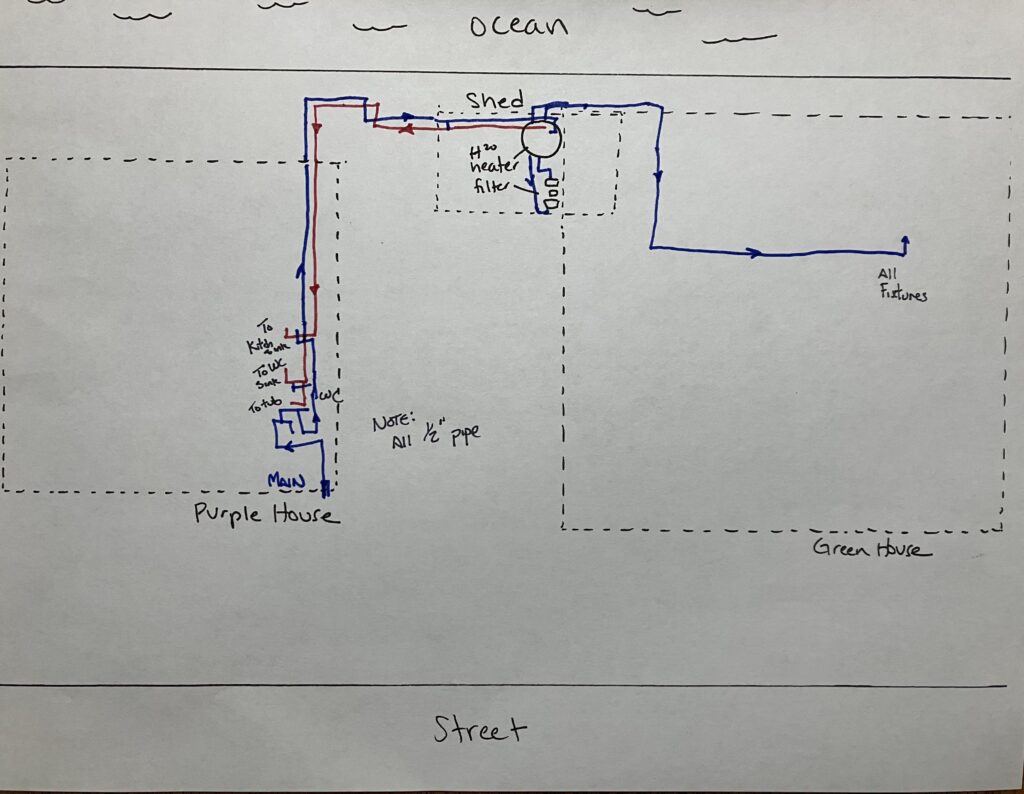

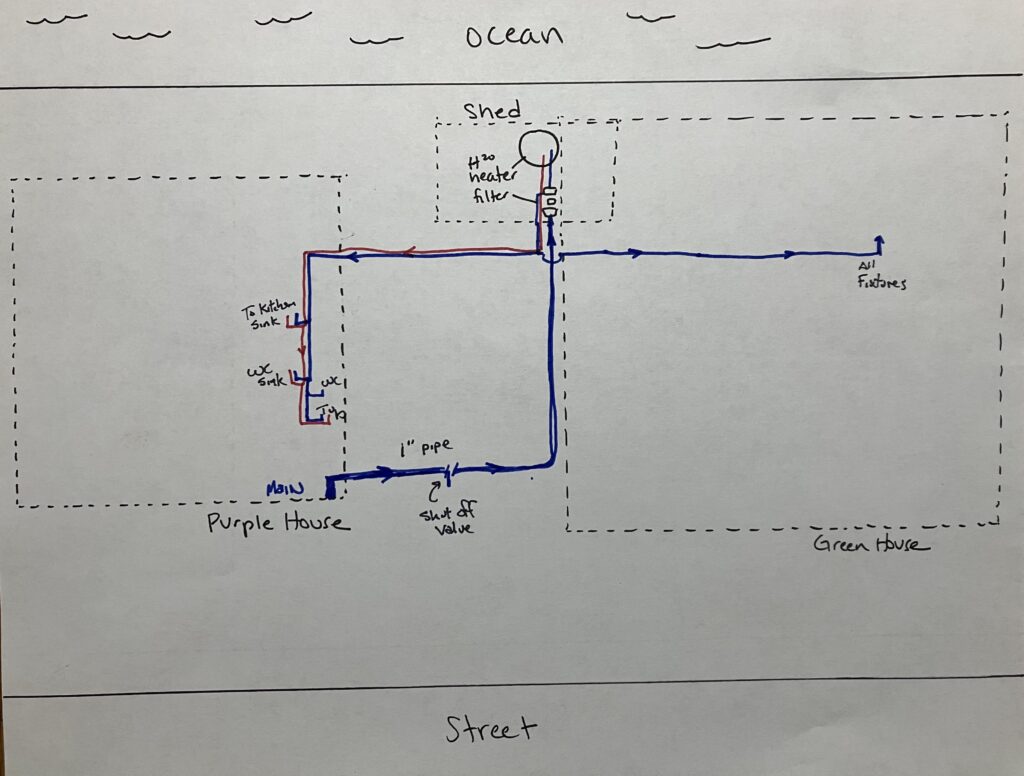

The main reason we *had* to go to Sitka was to do some plumbing work on our houses. (And by “we” I mean “Matthew”. I’m afraid I wasn’t much help on this project, but our friend Scott sure was!) The goal was to remap the crazy pipe route from this:

To this:

Notice in the “before” picture how the water for BOTH houses goes through the purple house first (after several crazy initial jigs and jags), then takes a long journey practically out to the ocean before heading into the shed, where the hot water heater for the purple house is located. Then the hot water goes back to the purple house while the rest of it goes through a filter in the shed, then over to the green house (where the hot water heater is located inside the house). Plus, it’s all 1/2″ copper pipes, which freeze easily unless watched hawkishly. Oh yeah, and we currently have no shut-off valve, so if anything were to burst, we have to call the city to shut off the water for our houses AND our neighbor’s.

The new plan is much more straight-forward: The main heads directly to the shed (via a new shut-off valve!), where all the water is filtered, then distributed appropriately to each house. Plus, we’re swapping out that copper for PEX pipes and wrapping them in heat tape and insulation.

This work involved spending many hours underneath the porch, often on rather cool and damp days.

Now we’re back in Virginia, making a big push on camper-building this week. One way or another, I need to get to Michigan by Monday night (9/19) to be with my sister for her next round of chemo. The ideal scenario would be to hook our little teardrop up to Twyla, load ’em both up with all our stuff, and use this trip to Michigan as the first leg west in our grand adventure! I’ll let Matthew give you the updates on that progress … stay tuned!

Hello from Alaska!

This photo was taken on a perfect sunny day in Juneau, and right now we’re in Sitka, sitting in the adorable kitchen of our friends Scott and Cleo, watching the gentle SE Alaska rain and listening to the backyard chickens fuss about their breakfast. It’s been fantastic to be back “home” for awhile. But more about that in a minute …

I guess it’s been awhile since you’ve heard anything from us besides camper building stories. There’s other stuff going on, too! First of all, let me say that I *love* my new job. (The one at the search firm, not the bartending job. Although that was fun, too, but between summer travels and camper-building, we needed to leave the bartending gig behind.) I’m working a few hours a day, keeping track of lots of details and having conversations with lots of smart, interesting people. I’m really grateful to have connected with this place and been given the opportunity to join their team. It’s definitely a big part of my week, and it’s so great that I’m able to bring the work with me and stay on top of it, even while we’re in Alaska!

Back in July, I went to Michigan for a couple of weeks to be with my sister Iris for her second round of chemo. She’s doing OK – her body seems to be tolerating the treatments as well as possible. There’s a lot of fatigue and frustration about how this changes her normal routine, but I really admire her courage, strength, and hopefulness. And I’m so glad to have the flexibility and availability to be able to spend time with her through this journey. While there, I overlapped for a couple of days with niece Sophia and her fella Brett – always excellent to spend time with them, too!

OH! And two rather AMAZING coincidences happened: 1) my flight to Michigan got cancelled, but a gate agent worked some magic and re-routed me through Philadelphia. Within 10 minutes I was sitting on a plane, texting my brother who lives 1/2 hr from PHL, and – hooray! – the timing was perfect for him to come pick me up to join them for dinner and crash at their house for the night before I continued on to Michigan the next day. 2) My college roommate and dear-friend-to-this-day, Emily, who now lives in NORWAY, just *happened* to come to a family memorial service in Grand Rapids while I was there! Fortunately she’d been tracking me enough to remember that I was in Michigan and we were able to have lunch together!

Here’s a few photos from my time in Michigan:

On August 14, we put down the camper project for a bit and set off on a 3-week trip to Juneau & Sitka. We spent 6 days in Juneau visiting several good friends; fortunately the weather was gorgeous, so we also got out on the trails a bit. Now we’re halfway through 2 weeks in Sitka, where we’re also enjoying lots of time with friends, but also doing a little plumbing project under our houses here. I haven’t been as good about taking photos, but here’s a few:

All the Pieces Fit

We took some big steps in the past five days! All the cabinets are built and installed, and the sides are now permanently attached. We are on a bit of a time crunch to get the outside road-ready (more on that in an upcoming blog post) so we are saving some of the interior finishing, cabinetry, and painting for later.

The next big steps are: getting the interior roof liner put into place, wiring, and then the exterior skins and paint! We are up for some big challenges figuring out how to bend the roof skins to the teardrop shape. Going to be a big learning curve.

The photos below are grouped by camper component, so some of the pictures are out of sequence from the actual build order, but it is easier to get the idea of what has happened so far.

Postcards from the Camper Build

The Build Is Going To Move a Bit Faster Now…

Some exciting things happened last week, on the same day! We got our trailer, and I got covid*!

*Well, I didn’t get tested. What I got was a five-day illness with flu-like symptoms consistent with the symptoms of the covid pandemic.

So, as agonizing as the wait has been for getting the metal part of the camper manufactured so that the rest can be built on it, I still had to wait until this week to be able-bodied enough to do anything about it.

We took the trailer to a friend’s shop to get it painted, welded, and tired. I don’t think we could have knocked out the trailer to-do’s without him. So, please raise a glass to Ed Hammond at your next social gathering.

There were a few goofy things that happened during the trailer build. I’ll have another chapter of “Lessons Learned” regarding those pretty soon, but for now, I need to get out there and start building that camper!

Scenes from the Kitchen Table

I was hoping for a trailer for my birthday, but I guess I get to practice patience some more times. So, I thought I would dive into the electronics a bit. Just practicing my soldering and making sure the battery and circuits will handle what we are asking of it.

Fun With Styrofoam

All the walls and bottom use styrofoam as insulation. We needed to trim some it the correct thickness, so I created a dangerous tool to do it, using broken chair legs and NiChrome wire. You can also marvel at the great sound and camera work – sorry about that.

Then I take that cardboard out from under the styrofoam, and it fits perfectly!

Small Step, Big News

Today I applied poly resin to completely waterproof a section of the side wall that will go against the metal part of the trailer. Epoxy resin is in every hardware store around here because of all the boats. I was describing the steps for the camper build to a friend of mine who lives on a sailboat, and he said, “Oh, just like building a boat – got it.” I think some of the steps for putting this thing together may be confusing to folks who are used to putting together houses. No screws here – the constant vibrations of the road would jiggle them loose. Everything is built to glue together whenever possible, with the storage compartments designed to add structure to the whole. Every seam is sealed, every exterior surface coated in plastic.

Not that I’ve ever built a boat before, either. With every step of the build, even at these early stages, I keep thinking, “The NEXT time I do this…” It is such a fun course in Applied Camper Building I’m taking!

And how about some more exciting news? My lead for welding the trailer paid off. I should be picking up the frame next week! I ask of you all to go to a social gathering and raise a glass and a cheer for Atlantic Metal Products of Topping Virginia. May their praises be heard across the land! This is a Grown-Up metal shop and I think welding this trailer is a way puny job for them, but through a barroom buddy connection the president of the company agreed to kick this out for Kayla and I. Expect the build to really kick into high gear next week!