Happy anniversary to us!! Many of you were there with us FIFTEEN YEARS ago to witness and help us celebrate our partnership and commitment — wow, those were an amazing couple of weeks! As some of you know, we were hoping to use our 15th anniversary as an excuse to bring all our lovely friends together again, maybe for a camp-out music jam grillfest extravaganza … one or two of you might have even marked it on your calendars? Don’t worry, it’s not that your invitation got lost in the mail, we just couldn’t pull it together this year. But it sure would be fun! Maybe next year?

We had such a long weekend at the Deltaville Tap last weekend. Both of us worked about 40 hours in 4 days, from open to close every day. Man, did we open a lot of beers and pour a lot of rum punch! Definitely exhausting, but there were some fun moments. On Monday we seized control of the bar music and chose an “essential 80s hits” playlist. Turns out 80s music really works for everyone! Our 20-something coworkers were bobbing their heads to the beat as they shucked oysters and delivered burgers. Parents explained to their children that Nena is German and that’s why she sings 99 Luftballoons with an accent. We could audibly hear people across the restaurant singing “Livin on a Prayer.” And we happened to have a bar full of 40/50-somethings who knew every word to every song, so it was a big fun singalong.

There are a couple of new, very young servers who have joined the staff. They’re sweet as can be, but bless their hearts, they know nothing about drinking and not so much about eating either. Some examples:

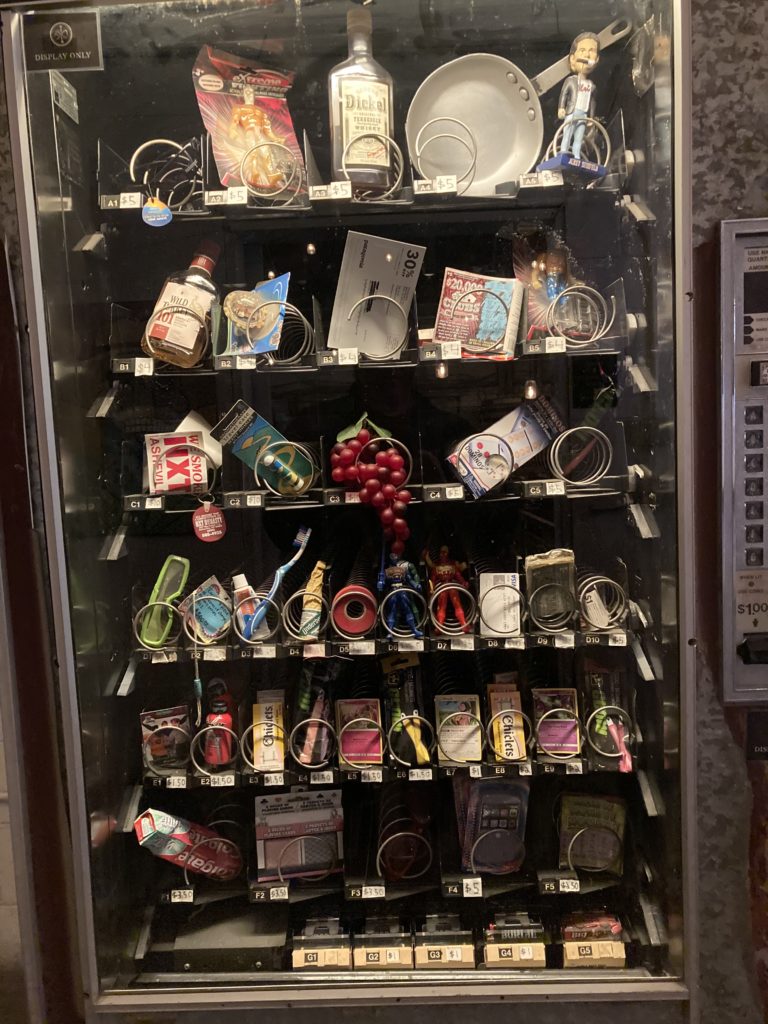

Very Young Server #1, while staring at the top shelf liquor bottles: “She wants a corona with lime, I’m just trying to see what liquor that is so I can ring it in.”

Very Young Server #1, again while staring at the top shelf liquor bottles: “They want a caboway, or something like that.”

Kayla: “Was it Cabo Wabo?” (which is a tequila)

VYS1: “Yes, that sounds right. I see ‘cabernet’ in the system, is that what I should use?”

And my favorite:

Very Young Server #2: “Did you get my order for a shrimp cocktail?”

Kayla: “A shrimp cocktail isn’t actually a drinking cocktail. It’s an appetizer, so that ticket would have gone to the kitchen.”

Poor things. That’s a steep learning curve!

One afternoon we had a fun family of five come in: older couple and three folks in their early 50s. They sat at the bar and had a grand old time, and talked with us a lot. They especially like Matthew and his crazy hair. It was a pretty busy day, so both of us were running back and forth, making lots of drinks, taking orders at the window, etc. The family watched us and commented on how well we work together, what great bartenders we are, etc. When they were getting ready to leave and paying, they asked me whether we would split their tip or should they tip each of us. I said we’d split it, but that it all ends up in the same place anyway because … we’re married! And all together the five of them shouted “HOORAAYYY!” like that was the best surprise and best news of the day. Hahahaaaa cracks me up.

I wish you could all sit at the bar and listen to our general manager keep the line cooks in order. He usually plays the role of expeditor, standing at the window to the kitchen shouting back to the staff what orders are coming in, what they should be paying attention to, making sure they get all the special instructions, and then getting plates into hands of servers to run them out to tables. He uses some great diner language to do this: “You got some crab puppies that just walked in.” “Watch out for that crab cake sandwich wearing O-rings.” And one day, after the sound of breaking dishes from the kitchen: “Danny, if you see the word ‘china’ on your next paycheck, it’s nothing about any sort of trip we’re sending you on.”

One of the owners of the restaurant was sitting at the bar with a couple of his friends the other night. He’s pretty arrogant, and can be rude and demeaning. This was kind of a fun exchange:

Kayla: (uses a 6-syllable word)

OwnerMan: Wow, big word! You went to college, didn’t you.

Kayla: Yep, sure did.

OwnerMan: Where did you go to college?

Kayla: Which time?

OwnerMan: You have a MASTER’S DEGREE?!?!

Kayla: (smiles)

OwnerMan: You could be pulling in $200K with that! What are you doing!?! (with a tone of “are you stupid” in his voice)

Kayla: I’m doing whatever I want to!

OwnerMan: Matthew, what about you?

Matthew: Masters of Science in Applied Sociology.

OwnerMan: WHAT!?!?!

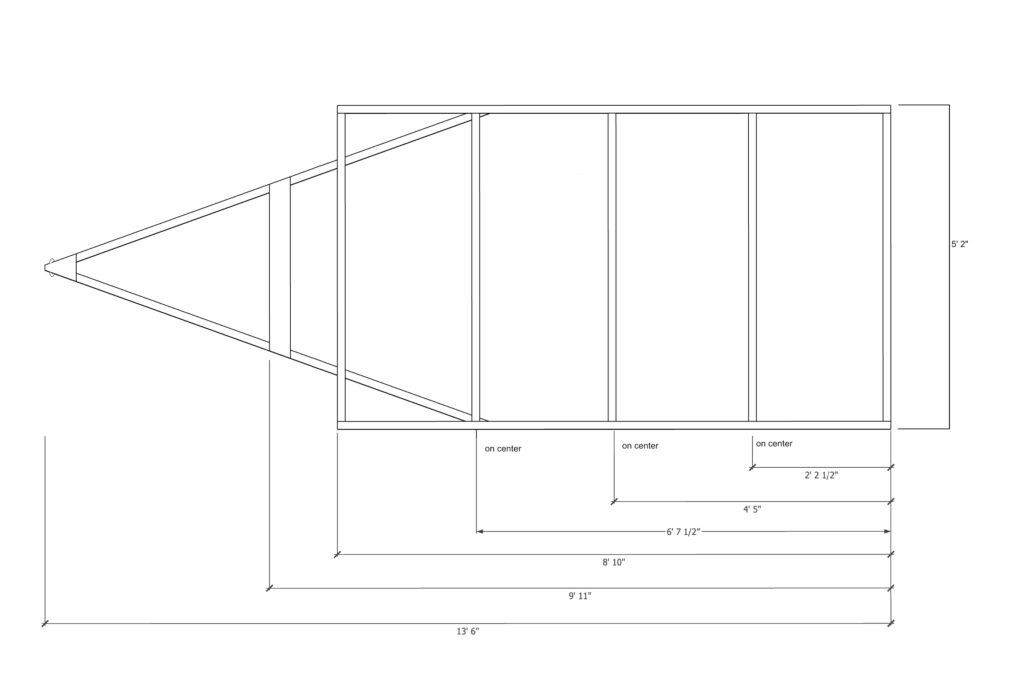

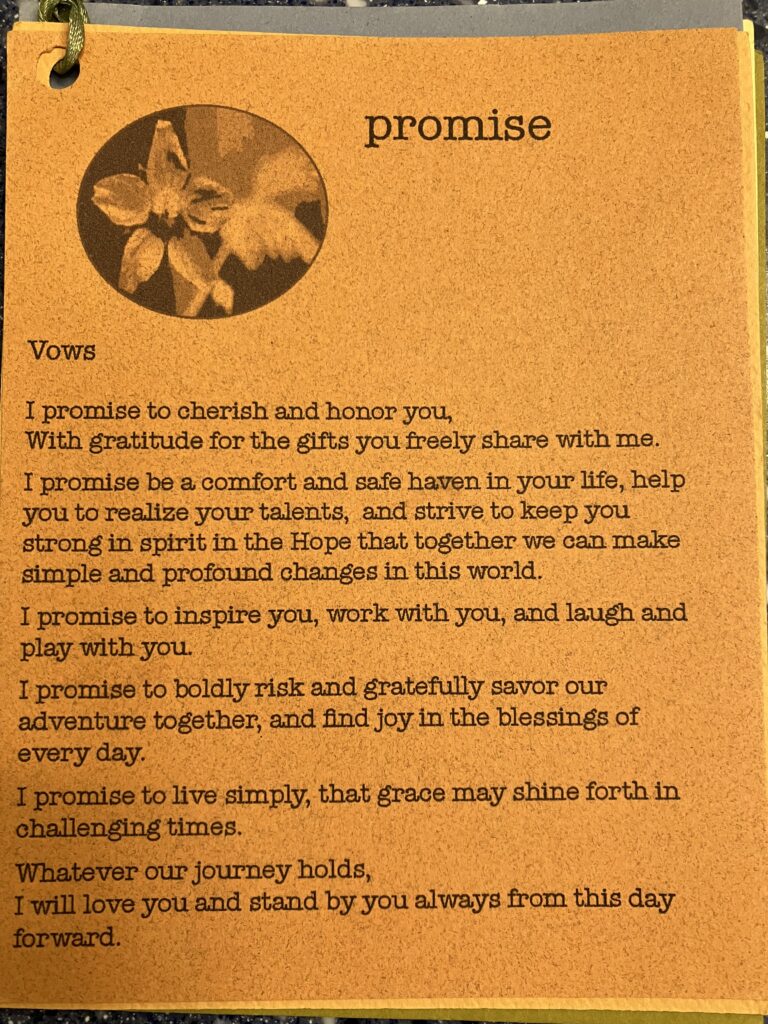

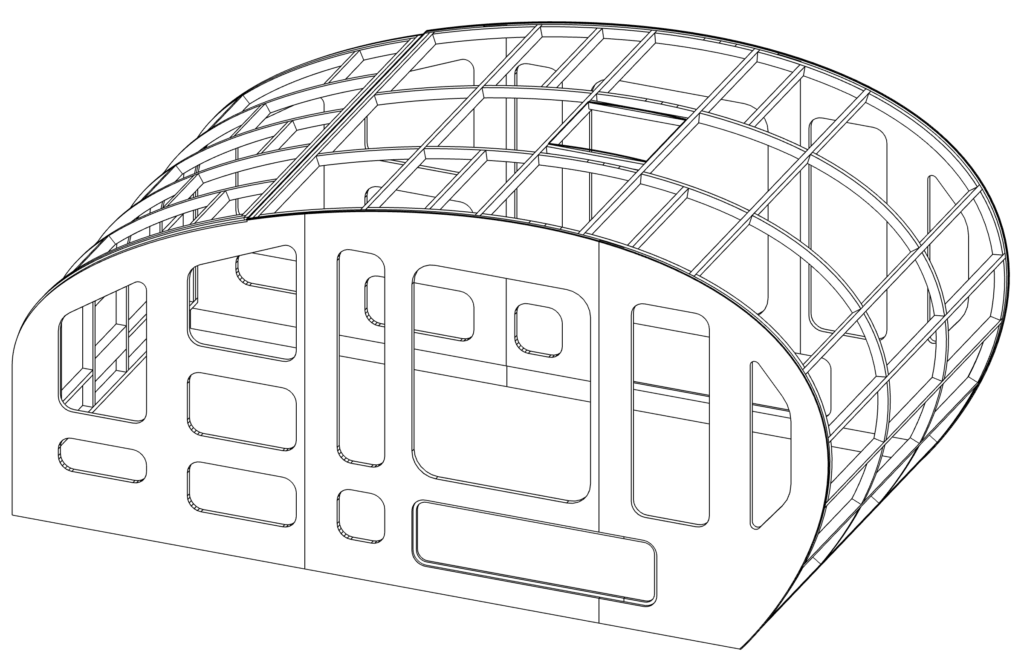

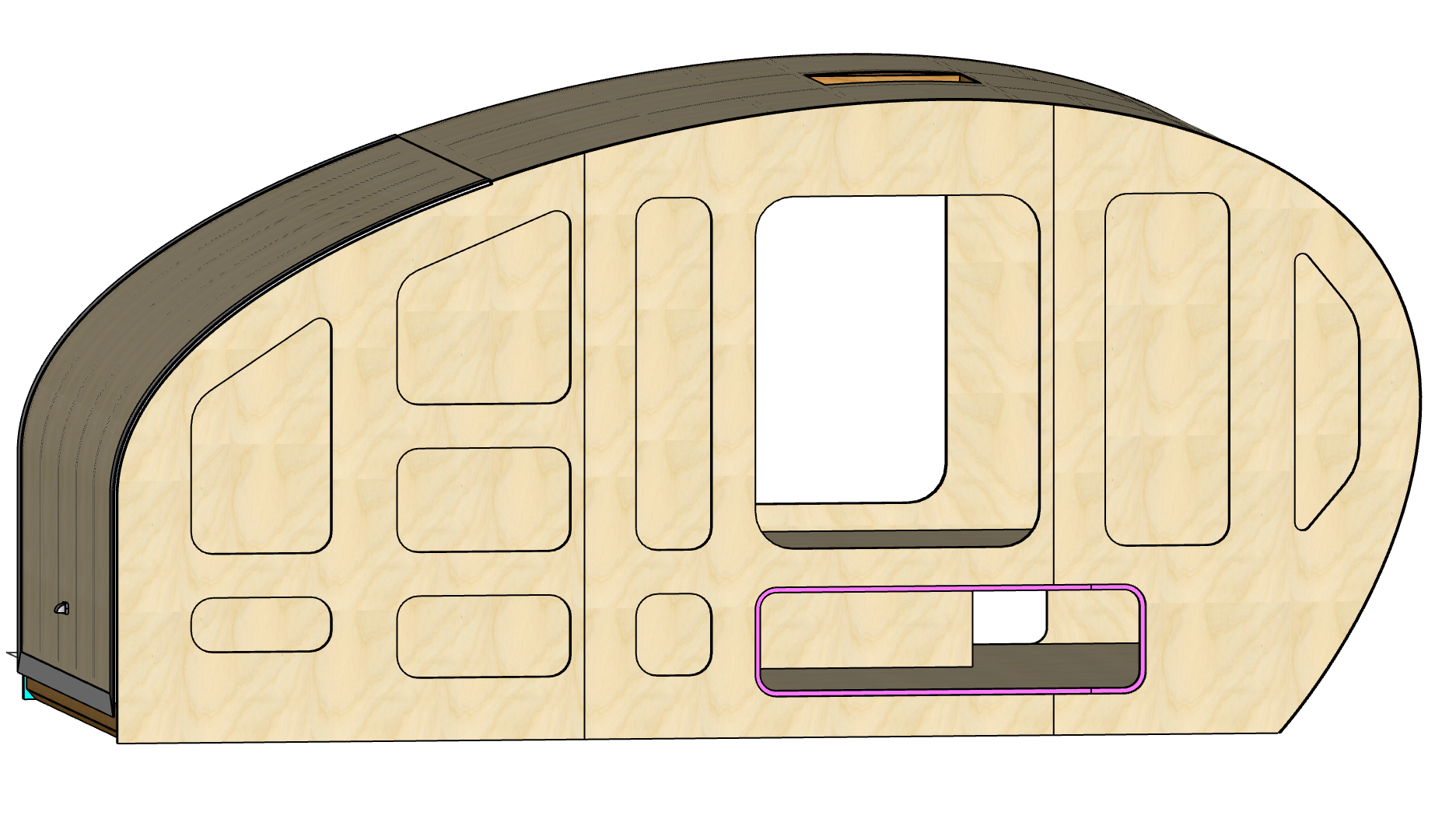

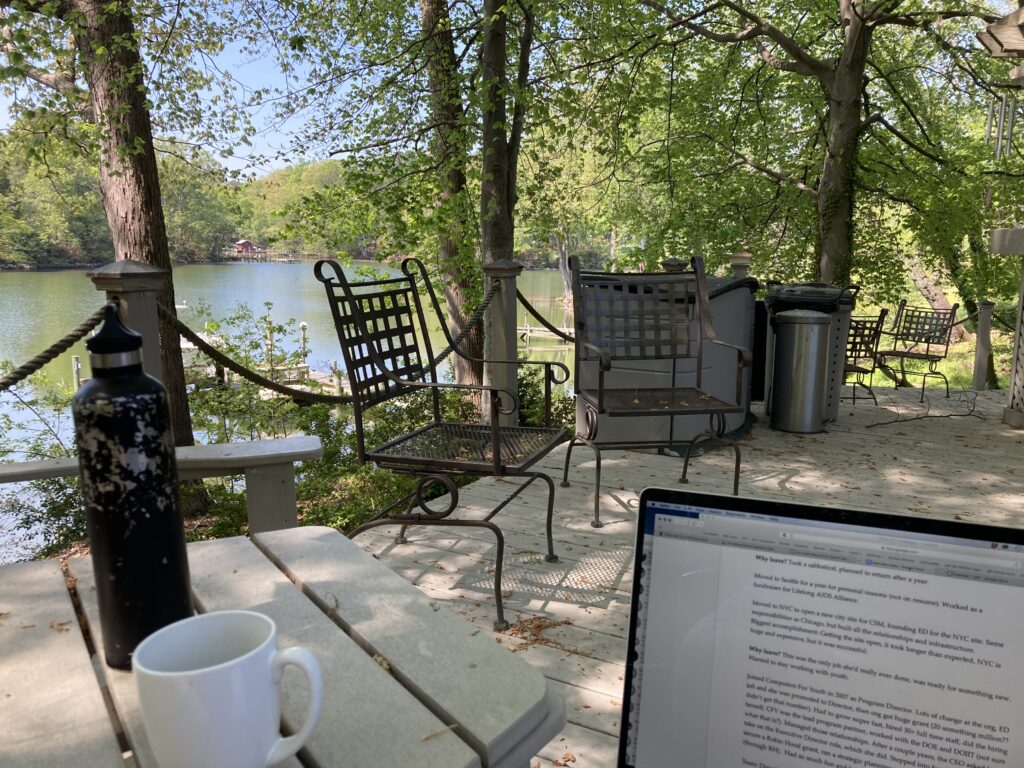

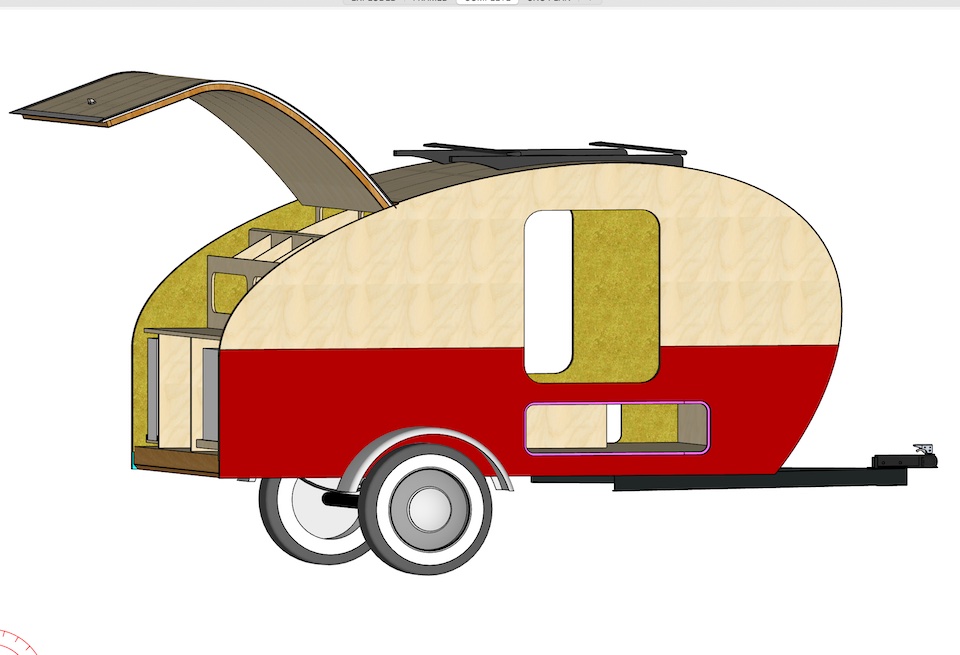

Ahhh … ha ha ha. It’s just not all about money for us. As we celebrate our anniversary today, I’m again full of gratitude and awe for how well Matthew and I live and work together, and how we share a vision for our life that prioritizes the people we love and an openness to new adventures, experiences, and perspectives. Although this past year hasn’t gone exactly to plan (notably: we thought for sure we’d have a camper built by now and we’d be off wandering around somewhere), I’m really glad for the significant time we’ve had in Michigan and here in Virginia, and appreciate all of this as part of the journey. Plus, I’m super grateful to have the flexibility and ability to spend time with family and friends when they need it most. So, cheers to you, Matthew. Let’s see what we can do with the next 15 years!