This photo was taken on a perfect sunny day in Juneau, and right now we’re in Sitka, sitting in the adorable kitchen of our friends Scott and Cleo, watching the gentle SE Alaska rain and listening to the backyard chickens fuss about their breakfast. It’s been fantastic to be back “home” for awhile. But more about that in a minute …

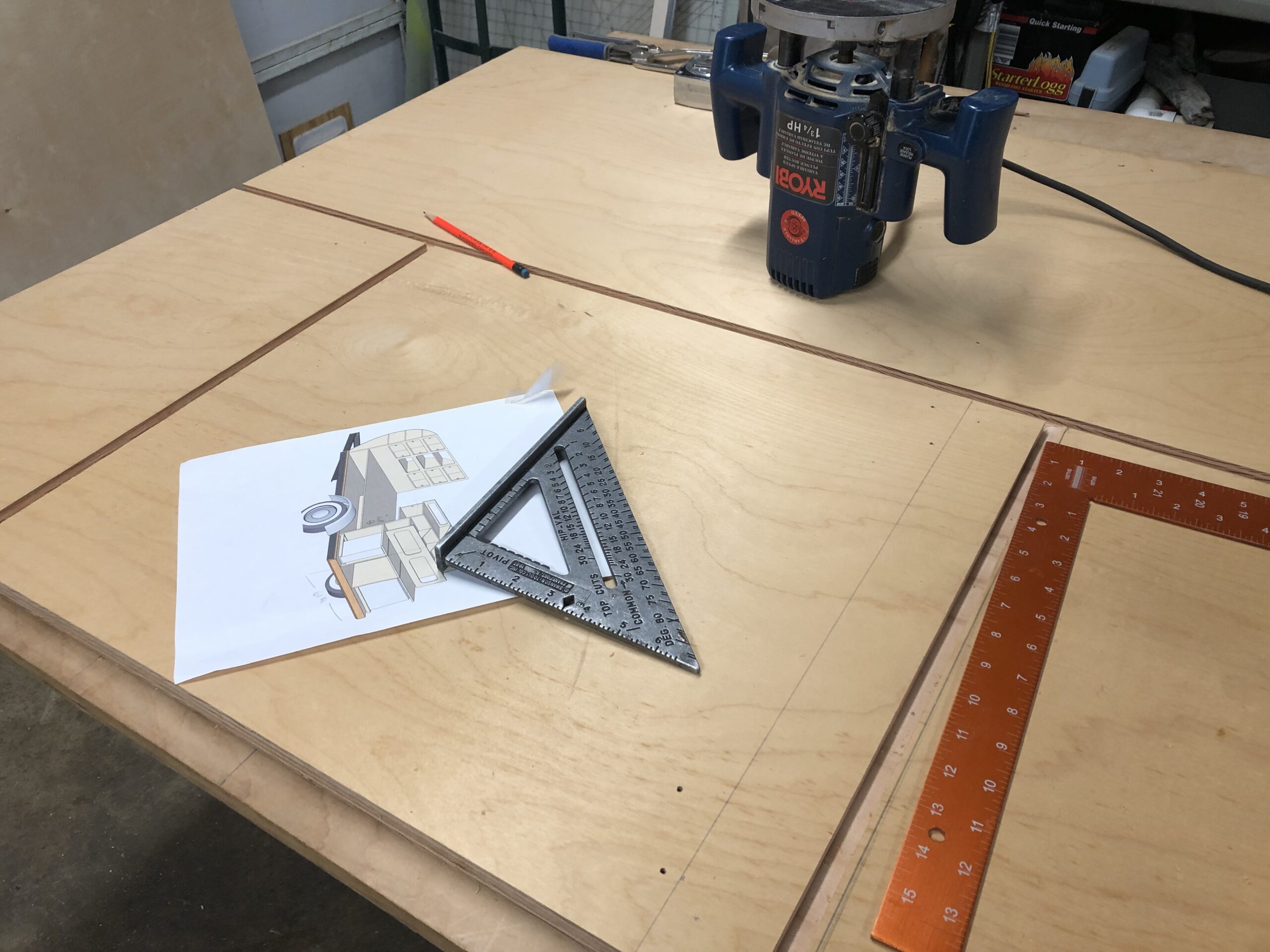

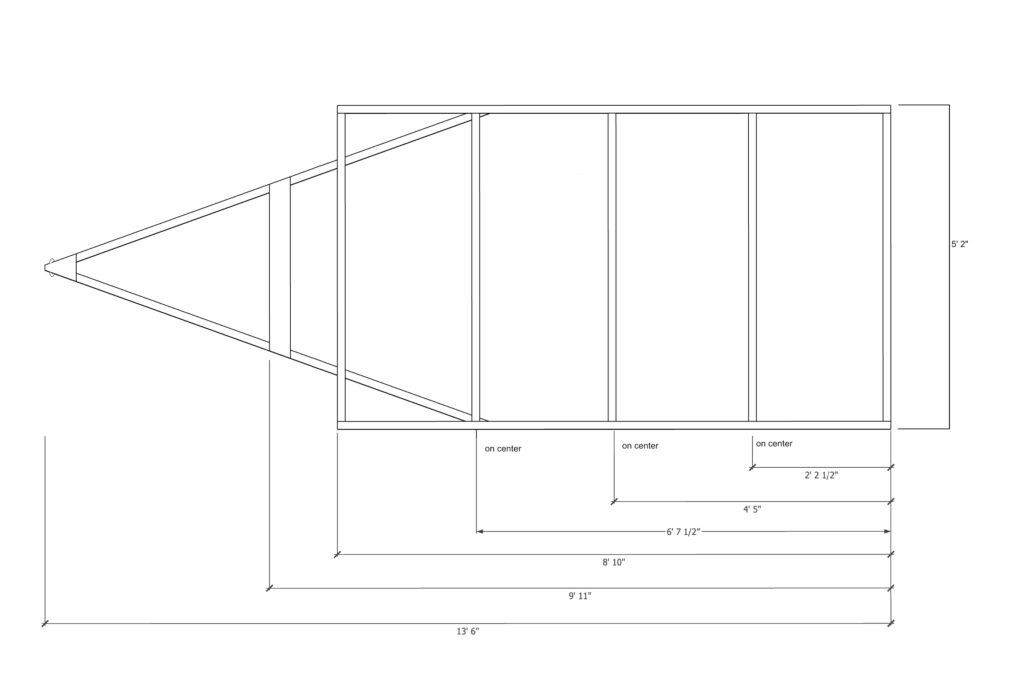

I guess it’s been awhile since you’ve heard anything from us besides camper building stories. There’s other stuff going on, too! First of all, let me say that I *love* my new job. (The one at the search firm, not the bartending job. Although that was fun, too, but between summer travels and camper-building, we needed to leave the bartending gig behind.) I’m working a few hours a day, keeping track of lots of details and having conversations with lots of smart, interesting people. I’m really grateful to have connected with this place and been given the opportunity to join their team. It’s definitely a big part of my week, and it’s so great that I’m able to bring the work with me and stay on top of it, even while we’re in Alaska!

Back in July, I went to Michigan for a couple of weeks to be with my sister Iris for her second round of chemo. She’s doing OK – her body seems to be tolerating the treatments as well as possible. There’s a lot of fatigue and frustration about how this changes her normal routine, but I really admire her courage, strength, and hopefulness. And I’m so glad to have the flexibility and availability to be able to spend time with her through this journey. While there, I overlapped for a couple of days with niece Sophia and her fella Brett – always excellent to spend time with them, too!

OH! And two rather AMAZING coincidences happened: 1) my flight to Michigan got cancelled, but a gate agent worked some magic and re-routed me through Philadelphia. Within 10 minutes I was sitting on a plane, texting my brother who lives 1/2 hr from PHL, and – hooray! – the timing was perfect for him to come pick me up to join them for dinner and crash at their house for the night before I continued on to Michigan the next day. 2) My college roommate and dear-friend-to-this-day, Emily, who now lives in NORWAY, just *happened* to come to a family memorial service in Grand Rapids while I was there! Fortunately she’d been tracking me enough to remember that I was in Michigan and we were able to have lunch together!

Here’s a few photos from my time in Michigan:

On August 14, we put down the camper project for a bit and set off on a 3-week trip to Juneau & Sitka. We spent 6 days in Juneau visiting several good friends; fortunately the weather was gorgeous, so we also got out on the trails a bit. Now we’re halfway through 2 weeks in Sitka, where we’re also enjoying lots of time with friends, but also doing a little plumbing project under our houses here. I haven’t been as good about taking photos, but here’s a few: